The Economist has a good article on the current state of 3D printing at 3D printing scales up.

Having been privileged to have watched several technologies evolve from early stage clunkiness to significant economic and cultural impact this seems like something to watch. It’s still very early days for 3D printing.

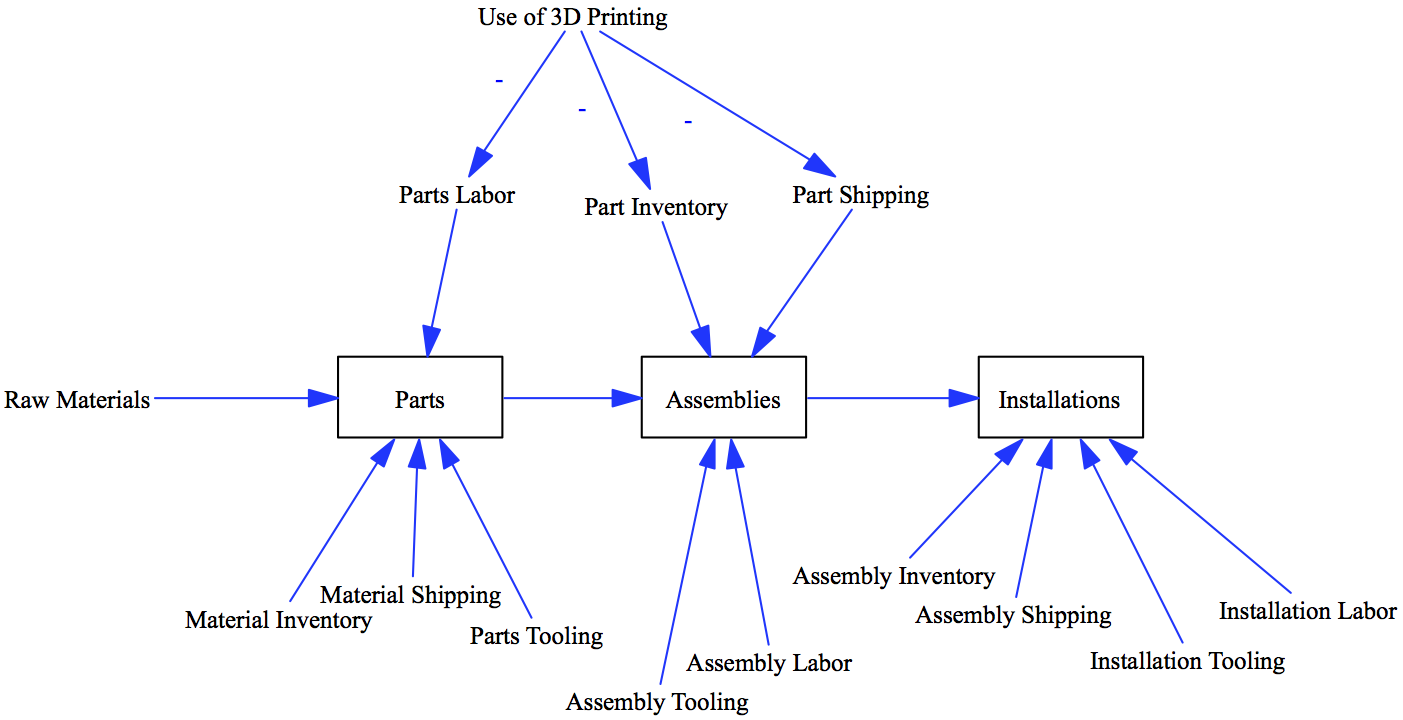

Looking at 3D printing in the context of a canonical supply chain, it seems like it might impact three areas: 1) The labor invested in creating parts. 2) The quantity of parts that need to be inventoried. 3) The need to ship parts from one place to another. This view does not address some of the other impacts that 3D printing may have such as the ability to create parts that are difficult any other way.

With respect to the labor invested in creating parts, 3D printing is an automated manufacturing process like many other automated manufacturing processes (dedicated tooling, robots, etc.). It’s impact is really not very different than those. That being said increased automation reduces the cost of part manufacture by both reducing the quantity of required labor and the skills required. This in turn may have the impact of reducing wages involved in part manufacture due to the reduction in skills required. The demand on this labor pool may go up if the number of locations goes up as mentioned below.

With respect to part inventories and part shipping; while part creation time may go up using today’s 3D printing technologies this can be traded off against part shipping time or the time to develop tooling using traditional manufacturing techniques. An interesting effect of this is that raw material inventories will move closer to points of assembly rather than be located at points of part assemblies as they are today. An important stock to examine may be the quantity of part manufacturing locations. It seems like this may increase with 3D printing. This in turn will have an impact on raw material shipping and storage. Another might be the impact on stocks of various kinds of tooling. 3D printing would provide a downward force to the variety of manufacturing tools, but possibly a upward force on the quantity of manufacturing tools.

This model is just a sketch that begins to frame what the picture may look like and the changes that may occur with the introduction of 3D printing. Given the questions above, a much more interesting model can be created that can be used to explore the impact of 3D printing.