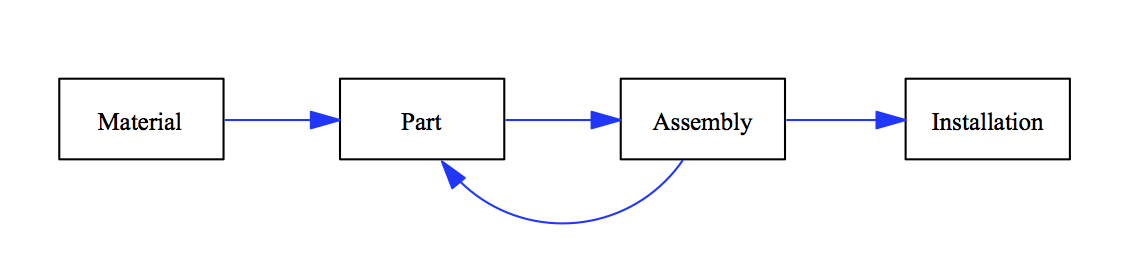

Just to provide a framework for discussion, and because I’m that kinda guy, I’ll define a canonical device supply chain as follows…

The definitions of each of these elements are not strict, in fact they’re pretty squishy, but they do provide some landmarks that enable certain kinds of descriptions.

Materials

A material is any substance used in the creation of a part. This material may have been extracted from nature or recycled from another part. It is generally monolithic in some sense. Most importantly its purpose has not yet been established. It may be applied to many different parts in a variety of ways.

Parts

Parts are objects used in assemblies. Note that a special case of an assembly may consist of only one part. A part is an arrangement of materials that play a role within an assembly. An assembly may be a part, a subassembly, that is used in other assemblies. Mechanical parts tend to play roles based on their shape and material characteristics, electrical parts play roles based on their electromagnetic characteristics, informational parts play roles based on the information that they encapsulate and produce, etc.

Assemblies

Assemblies are collections of parts arranged to address a particular purpose. Assemblies may be arranged hierarchically as subassemblies fitted together into higher level assemblies. A special case of an assembly is a single part. Assemblies may be very abstract. For example, a phonebook in an information context is an assembly of phone numbers. Of course, in a mechanical context, a phonebook is an assembly of pages. The pages are parts of the phonebook assembly. Each page is an assembly of ink and paper. The ink and paper are parts of these assemblies. The ink and paper are manufactured from materials.

Installations

An installation is an instantiation of an assembly in a particular context in order to achieve some purpose associated with that context. The door to my room is an assembly instantiated specifically to my room in order to be able to close it off from the outside world. It could have been used elsewhere but happened to be used for my room. Note that there is no implication that context is necessarily geographically static. A diesel engine in a locomotive moves around, but the installation context is the locomotive.

Why stop at installation, and not include support, operation, disposal, etc? There are supply chains associated with repair and upgrade components, for example, which may be different than the original assemblies. Just curious what kind of systems you’re interested in exploring.

Good point, Jim. There is the entire lifecycle view of a device and it does take on even more of a fishbone appearance when you add these things in.

This was biased a bit by a recent article on 3D printing. 3D printing seems to be good for creating a certain class of objects that I describe as “parts” within this framework. If you look at a lot of pre-acquisition supply chains today a lot of parts are manufactured in a location separate from “final” assembly. This seems to restrict 3D printing to a particular niche in this portion of the supply chain. Of course, it could provide a “just in time” part provisioning mechanism at a point of final assembly as well, which is another possible impact.

Your comment illustrates that my framework is incomplete for this consideration since one of the interesting areas for 3D printing is support or repair of an already deployed device. I’ll ponder this and extend the picture.